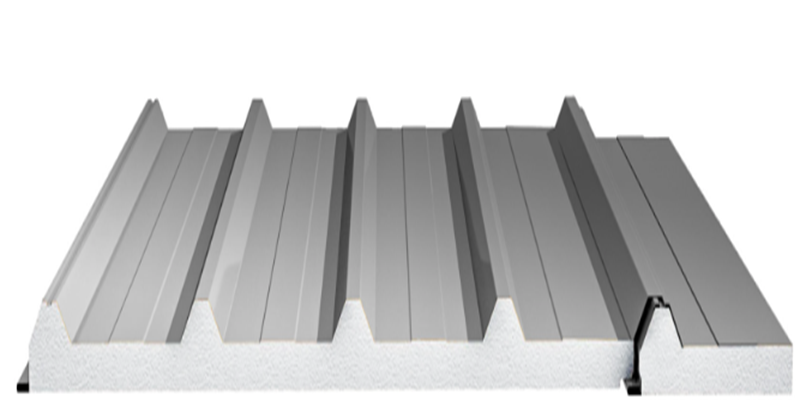

When it comes to sandwich panel construction, selecting the right core material is crucial for ensuring the desired performance in terms of heat insulation, sound insulation, fire protection, and strength. The core materials vary in composition, each offering unique benefits depending on the specific requirements of the application.

Foam Core Panels

Foam cores, particularly polyurethane (PUR) and polyisocyanurate (PIR), are among the most popular choices for sandwich panels. Polyurethane core panels offer excellent initial thermal insulation properties, making them ideal for applications where energy efficiency is a top priority. However, their fire resistance is somewhat limited compared to other materials. To address this, PIR panels were developed as an improved version of PUR, offering enhanced fire resistance, thermal insulation, and stability. PIR panels are well-suited for both industrial and residential applications requiring superior fire safety.

Phenolic foam (PF) core materials, though more expensive than PUR and PIR, offer even better fire resistance and slightly higher thermal insulation. These panels are often chosen when fire protection is a critical factor, though the higher cost may be a consideration in budget-conscious projects.

Polystyrene foam core panels, particularly expanded (EPS) and extruded (XPS) polystyrene, provide an economical alternative. EPS panels are widely used in cost-sensitive projects but offer lower thermal and fire resistance than PUR or PIR. XPS, on the other hand, has a higher density, providing better thermal resistance, moisture, and steam resistance than EPS, making it a solid choice for environments prone to dampness.

Non-Foam Core Panels

For applications where fire resistance and sound insulation take precedence, mineral wool core panels stand out. Mineral wool is a non-combustible material, offering excellent fire protection and superior soundproofing capabilities. However, it is heavier than PIR and has lower thermal insulation, making it more suitable for projects where fire resistance is prioritized over thermal efficiency.

Honeycomb Core Panels

Honeycomb structures, commonly made from aluminum, polypropylene, or cardboard, are known for their high strength-to-weight ratio, making them ideal for applications where mechanical strength is critical. However, they do not provide the same level of thermal insulation as foam-based panels, making them less suitable for projects where heat insulation is a priority.

In summary, the choice of core material depends on the specific requirements of the project. PUR and PIR cores are excellent for thermal insulation, while mineral wool excels in fire resistance and sound insulation. For strength-focused applications, honeycomb cores may be more appropriate, though they lack thermal efficiency. Each core material offers a distinct set of advantages, and the best choice ultimately depends on the balance of performance needs such as insulation, fire safety, and structural integrity.

Post time: Sep-20-2024