As a leading supplier of polyurethane catalysts, we are pleased to highlight the important role these catalysts play in the production of polyurethane foam, a versatile material used in a variety of industries. Our products, including MXC-A33, MXC-T and a variety of other specialized catalysts, are an integral part of the polyurethane foam manufacturing process, ensuring efficient reactions and high-performance results.

How Polyurethane Foam Is Made

Polyurethane foam is produced through a chemical reaction between diisocyanates and polyols, both of which are derived from crude oil, though polyols can also be synthesized from renewable natural oils. This reaction results in a polymer chain that forms the core structure of the foam. Polyurethane foam production involves six main components:

- Polyols: The primary building block of the foam, reacting with diisocyanates.

- Diisocyanates: Key reactants that combine with polyols to create the foam.

- Foaming agents: These help form the cellular structure of the foam.

- Surfactants: Stabilize the foam during its expansion process.

- Catalysts: Speed up the reaction between polyols and diisocyanates, ensuring optimal foam formation.

- Hardeners: Crosslinkers and chain extenders are used to enhance foam rigidity and performance.

When these ingredients are combined, they chemically react, generating heat, gas, and the foam’s characteristic structure. Catalysts like our MXC-A33 and MXC-T facilitate this reaction, ensuring a controlled and efficient process.

Catalyst Applications in Polyurethane Foam

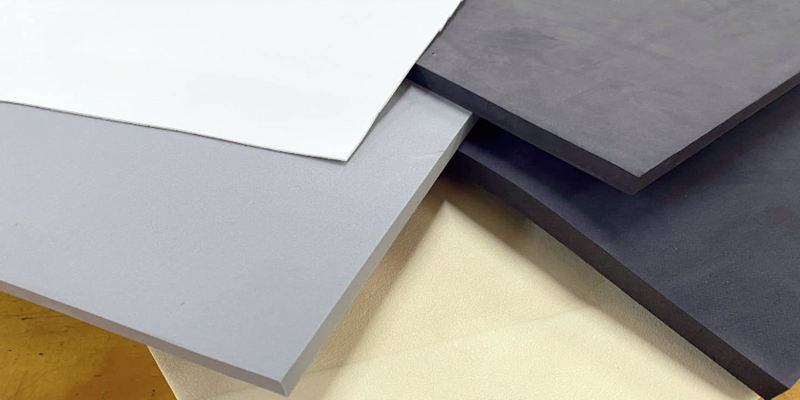

Polyurethane foam comes in two primary types: rigid and flexible. The applications range from insulation in construction (rigid foam) to cushioning in furniture and automotive interiors (flexible foam). Our catalysts are tailored to suit various needs:

-MXC-A33:A catalyst composed of 33%TEDA (triphenylenediamine) and 67%DPG (monoconjugated dipropylene glycol), specifically designed for polyurethane foams and polyurethane elastomers. Widely used in soft, semi-rigid, rigid polyurethane foam, coating, elastomer.

-MXC-T: It is an efficient, emission-free amine catalyst that provides a smooth reaction curve and can therefore be used to produce various types of polyurethane foams. Its catalytic action promotes the reaction of urea (water-isocyanate), which is prone to react with the polymer matrix due to its active hydroxyl group. For this reason, TMAEA is used to spray foam insulation, automotive dashboards, and other areas that require low residual odors.

Polyurethane catalysts ensure proper reaction rates, fine-tuning foam properties such as density, hardness, and structural integrity. This precision enables polyurethane foam to meet the stringent demands of modern industries, including construction, automotive, furniture, and packaging.

About Us

We are a leading supplier of high-performance polyurethane catalysts, committed to delivering innovative solutions for diverse industrial applications. Our extensive product line helps manufacturers optimize foam production processes while meeting environmental and regulatory standards.

Post time: Oct-23-2024