Polyether polyurethane foams have revolutionized various industries with their versatile applications and superior properties. Our brand, MXC-RE13, with the product name N,N,N’-trimethyl-N’-hydroxyethyl-bisaminoethylether, plays a pivotal role in enhancing the production of these high-performance foams. MXC-RE13 is a low odor, low emission, and highly reactive blown catalyst specifically designed for the production of polyether polyurethane HR foam, molded foam, packaging foam, and multi-density water-blown spray foam.

Key Applications of Polyether Polyurethane Foam

1. High Resilience (HR) Foam

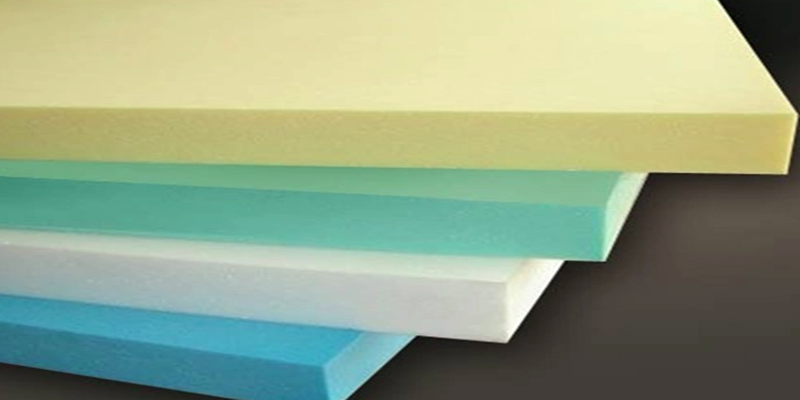

Polyether polyurethane HR foam is known for its high resilience, flexibility, and excellent tear and wear resistance. These properties make it ideal for use in the furniture and bedding industries. HR foams provide superior comfort and support, ensuring durability and long-lasting performance in mattresses, cushions, and upholstered furniture. The use of MXC-RE13 catalyst ensures efficient production processes, resulting in consistent quality and enhanced product performance.

2. Molded Foam

Molded polyether polyurethane foam is widely used in automotive and aerospace industries for seating and interior components. The flexibility and durability of these foams contribute to enhanced comfort and safety in vehicle seats, armrests, and headrests. The MXC-RE13 catalyst accelerates the reaction rate between polyols and isocyanates, ensuring the production of high-quality molded foams that meet stringent industry standards.

3. Packaging Foam

The protective qualities of polyether polyurethane foam make it an excellent choice for packaging applications. This foam offers superior shock absorption and cushioning, protecting delicate and valuable items during shipping and handling. The low odor and low emission characteristics of MXC-RE13 make it suitable for use in environments where minimal environmental impact and user safety are paramount.

4. Multi-Density Water Blown Spray Foam

Polyether polyurethane foams are also used in construction and insulation applications, particularly as multi-density water-blown spray foam. This foam provides excellent thermal insulation, reducing energy costs and improving building efficiency. The foam’s resistance to oil, water, fungal, and mold growth ensures long-lasting performance in various environmental conditions. The high reactivity of MXC-RE13 enhances the efficiency of spray foam application, ensuring thorough coverage and effective insulation.

Additional Benefits of Polyether Polyurethane Foam

Beyond the specific applications mentioned, polyether polyurethane foams offer several other benefits. They serve as excellent seals, buffers, and shock absorbers in a variety of industrial applications. Their superior tear and wear resistance extend the lifespan of products in which they are used. Additionally, the inherent properties of these foams make them suitable for surface protection, ensuring that surfaces remain intact and undamaged during use and transportation.

Conclusion

MXC-RE13 catalyst plays a crucial role in the production of polyether polyurethane foams, enabling the creation of versatile, high-performance materials that meet the demands of various industries. Whether used in HR foam for furniture, molded foam for automotive interiors, protective packaging foam, or insulating spray foam, polyether polyurethane foams offer unparalleled performance and reliability. As a supplier of MXC-RE13, we are committed to providing catalysts that enhance the production process, ensuring the delivery of top-quality foams that meet the diverse needs of our customers.

Post time: Jul-30-2024