As the global demand for environmentally sustainable products rises, industries are shifting to greener alternatives in various applications. In the polyurethane foam industry, Hydrofluoroolefin (HFO) blowing agents have emerged as a groundbreaking solution due to their lower Global Warming Potential (GWP) compared to traditional Hydrofluorocarbon (HFC) and Hydrochlorofluorocarbon (HCFC) agents. For manufacturers of HFO blowing agents, the integration of efficient catalysts is crucial for optimizing foam production and ensuring the highest performance of the final product.

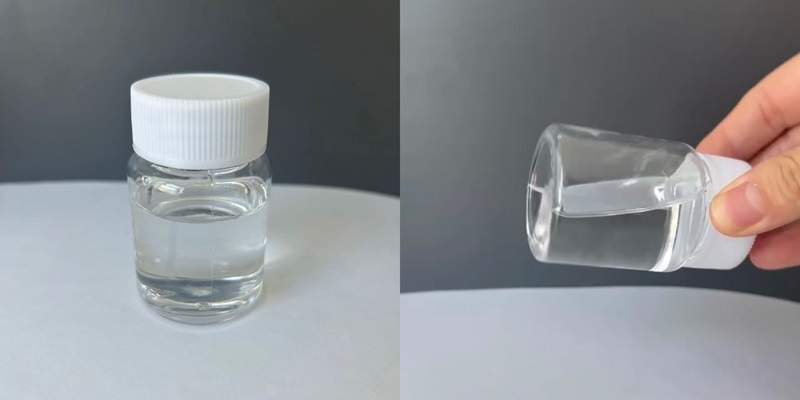

At Mingxu, we specialize in developing cutting-edge polyurethane catalysts to complement and enhance the performance of HFO-based blowing agents. One of our standout products, MXC-70, is designed specifically for systems using water as a co-blowing agent and has proven to deliver superior results in various flexible and rigid polyurethane foam applications, including appliances, rigid panels, and spray foams.

How MXC-70 Supports HFO-Based Foam Systems

1. Improved Surface Cure and Adhesion

In systems that incorporate HFO blowing agents, achieving a fast and thorough surface cure is essential for ensuring high product quality and durability. MXC-70 helps facilitate this process by enhancing the surface cure of polyurethane foams, leading to smoother and more uniform finishes. Additionally, it boosts substrate adhesion, ensuring strong bonding between layers and components—vital for the integrity of rigid foam panels and spray foams.

2. Smooth Rising Curve and Longer Shelf Life

MXC-70 offers a controlled, smooth rising curve, essential for producing foams with consistent density and uniformity. This catalyst ensures that the foam rises predictably and evenly, which is critical for manufacturing applications such as appliance insulation and sandwich panels. Furthermore, MXC-70 helps extend the shelf life of rigid foam systems, providing manufacturers with greater flexibility in storage and use.

3. Support for HFO Blowing Agents and Lower VOC Emissions

In line with the industry’s move toward greener practices, MXC-70 aids in the transition to HFO blowing agents, which have significantly lower GWP footprints compared to HFCs and HCFCs. By promoting efficient foam formation with HFOs, MXC-70 helps manufacturers achieve their environmental goals while also reducing VOC emissions. This dual benefit positions MXC-70 as a key catalyst for companies looking to produce high-performance, eco-friendly foams.

4. Suitable for Water as a Co-Blowing Agent

Water is often used as a co-blowing agent in polyurethane foam production, contributing to foam expansion and reducing the overall environmental impact. MXC-70 is particularly suited for such systems, optimizing the foaming process to achieve a balance between water and HFO. This results in foams with enhanced insulation properties and structural integrity, ideal for applications like rigid foam panels and appliance insulation.

Partner with Us for Sustainable Foam Solutions

For companies involved in the production and manufacture of HFO blowing agents, choosing the right polyurethane catalyst is critical to maximizing foam quality and production efficiency. Our MXC-70 catalyst is designed to complement HFOs, providing superior surface cure, adhesion, and overall foam performance while supporting sustainability goals. With its ability to reduce VOC emissions and enable the adoption of HFOs with a lower GWP, MXC-70 is an ideal choice for forward-thinking manufacturers.

If you are interested in learning more about how MXC-70 can enhance your HFO-based foam systems, please contact us at info@mingxuchem.com. We look forward to discussing how our advanced polyurethane catalysts can help you achieve your production and environmental objectives.

Post time: Mar-05-2025