Polyurethane has long been recognized as a highly adaptable material, and its versatility makes it an ideal choice for a variety of industrial applications, particularly in Coatings, Adhesives, Sealants, and Elastomers (CASE). These applications demand high-performance catalysts that can optimize reaction kinetics while ensuring superior product performance. For manufacturers of polyurethane systems, selecting the right catalyst is key to balancing efficiency, safety, and product longevity.

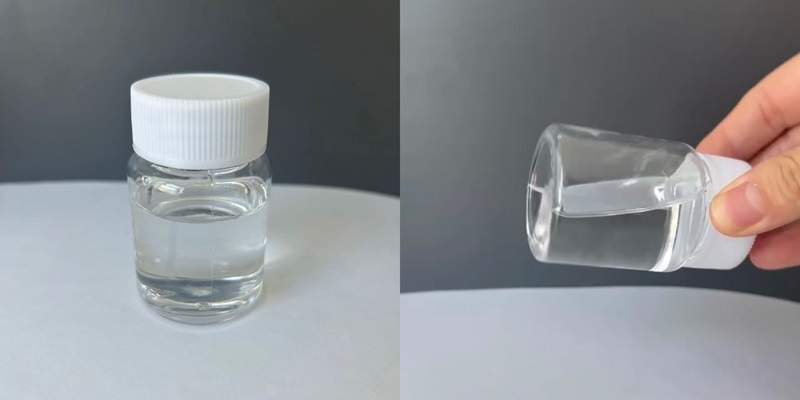

Our range of high-performance polyurethane catalysts offers solutions tailored to the specific needs of CASE applications, helping formulators achieve excellent properties such as adhesion, flexibility, and resistance to environmental factors. Among our leading catalysts, MXC-R70 (2-(2-dimethylaminoethoxy)ethanol, CAS 1704-62-7) stands out for its reactivity and suitability across a variety of foam forms and elastomeric products.

The Role of Catalysts in CASE Applications

Catalysts serve as the backbone of the chemical reactions that transform liquid polyurethane formulations into durable, high-performance products. They accelerate both the foaming (blowing) and curing (gelling) reactions, ensuring that the final product possesses the desired mechanical and physical properties.

In CASE applications, this means enhancing critical factors such as:

- Adhesion: Ensuring the strong bond between surfaces, which is essential in adhesives and sealants.

- Flexibility and Durability: Achieving long-lasting elasticity and resistance to wear in elastomers.

- Surface Finish: Improving the uniformity and aesthetic properties of coatings.

- Processing Efficiency: Facilitating faster production cycles with optimized cure times.

Key Applications of MXC-R70 in CASE

MXC-R70, a volatile amine catalyst, plays a crucial role in producing various polyurethane-based products, including microcellular foams and elastomers. Its high reactivity makes it particularly suitable for vinyl foam forms such as automotive dashboards and headrests, where precision and durability are required. By promoting rapid curing without compromising the flexibility and comfort of the foam, MXC-R70 is essential for applications that demand both high performance and comfort.

Key Features of MXC-R70:

- High reactivity: Allows for efficient and quick reaction times in both foaming and curing processes.

- Versatile applications: Suitable for a broad range of uses, from microcellular foams to elastomers, providing excellent physical properties in each application.

- Low toxicity: Reduces the reliance on toxic metal catalysts like dibutyltin, ensuring safer production processes for workers and manufacturers.

Reducing Exposure to Toxic Catalysts

A growing concern in the polyurethane industry is reducing exposure to toxic metal catalysts such as dibutyltin. Our innovative range of catalysts, including MXC-R70, offers a safer alternative by minimizing or eliminating the need for these harmful substances. This not only improves workplace safety but also aligns with evolving environmental regulations and consumer demands for cleaner, greener products.

Conclusion

Post time: Mar-11-2025